Struggling with motor efficiency? Bearings hold the key to smoother performance and longer lifespan.

Bearings in DC motors reduce friction, support rotational movement, and ensure efficient operation across various applications.

Learn how bearings affect DC motor performance1 and which types of bearings in DC motors2 fit your needs.

What’s a bearing?

Bearings reduce friction and allow smooth rotational movement. They are essential in DC motors for efficiency and stability.

Bearings are mechanical components that minimize friction and support rotational motion in various machines.

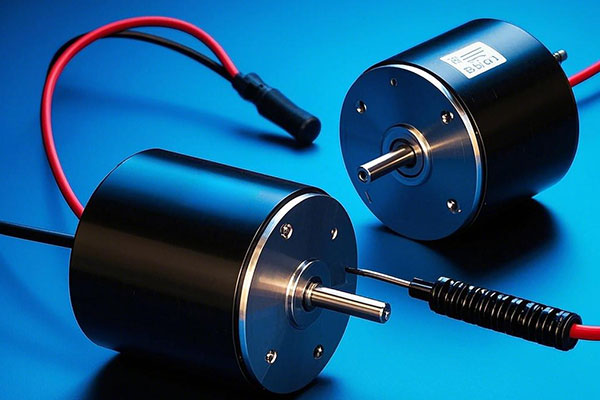

Bearings in DC motors come in different types, each designed for specific needs. For instance, ball bearings3 excel in high - speed applications, while sleeve bearings4 work best under consistent loads.

Types of Bearings in DC Motors

| Bearing Type | Bearing Picture | Key Features | Typical Use Cases |

|---|---|---|---|

| Ball Bearings3 |  |

Low friction, high speed | Electronics, precision machinery |

| Sleeve (Plain) Bearings4 |  |

Calme, durable under load | HVAC systems, household fans |

| Roller Bearings5 |  |

Handles heavy loads | Industrial machines, conveyor belts |

| Angular Contact Bearings6 |  |

Support combined radial and axial loads | High - speed applications |

| Thrust Bearings7 |  |

Designed to handle axial loads | Vertical shafts, automotive uses |

| Magnetic Bearings8 |  |

Contactless, no lubrication needed | High - vitesse, precision applications |

| Jewel Bearings9 |  |

Low friction, used in precision instruments | Clocks, measuring devices |

| Fluid Bearings10 |  |

Support load using a thin layer of liquid or gas | High - speed turbines, compressors |

What can bearings do?

Improve efficiency, reduce wear, and enhance performance. Bearings protect motors by minimizing energy loss and heat generation.

Bearings enhance DC motor performance by ensuring smooth rotation, reducing energy loss, and increasing durability.

Beyond smooth movement, bearings help to stabilize the motor shaft and ensure consistent torque. Properly chosen bearings can also extend a motor's lifespan significantly, especially under demanding conditions.

How Bearings Impact Efficiency

- Reduced Friction: Minimizes energy waste11.

- Heat Management: Prevents overheating12.

- Durability: Reduces wear on motor components13.

How do different bearings work in different applications?

Different bearings are tailored for specific needs, from high - speed to heavy - load applications. Each type has unique strengths.

Ball, sleeve, roller, and other bearings serve distinct purposes, depending on load, vitesse, and operational demands.

Selecting the right bearing type is critical for optimal performance. Par exemple, ball bearings are preferred in high - speed applications, while sleeve bearings excel in quieter, continuous operations. Roller bearings are ideal for heavy - duty use.

Comparing Bearing Types in Real - World Scenarios

| Scenario | Ideal Bearing Type | Why? |

|---|---|---|

| High - speed cooling fans | Ball Bearings | Low friction, high speed |

| Quiet HVAC systems | Sleeve Bearings | Minimal noise, durability |

| Heavy industrial machines | Roller Bearings | Supports heavy loads |

| Precision instruments | Jewel Bearings | Low friction, high accuracy |

| High - speed turbines | Fluid Bearings | Support high - speed rotation without contact |

| High - speed applications | Magnetic Bearings | Superior performance |

Matching Bearings to Your Needs

- Precision Tasks: Opt for ball or jewel bearings for accuracy.

- Continuous Load: Sleeve bearings are quieter and durable.

- Heavy - duty Work: Roller bearings handle stress well.

- High - Speed Applications: Magnetic Bearings or Fluid Bearings offer superior performance.

Which one is the best?

No single bearing type is universally the best. The right choice depends on speed, load, and operational needs.

The best bearing depends on application - specific factors like speed, load, and environment.

Each type of bearing offers unique advantages. For instance, ball bearings are efficient for speed, while roller bearings thrive under heavy loads. The key is to analyze your specific application and choose accordingly.

Factors to Consider When Choosing Bearings

| Factor | Importance | Example |

|---|---|---|

| Speed | High - speed needs ball or magnetic bearings14 | High RPM fans |

| Load | Heavy loads need roller bearings15 | Conveyor belts |

| Noise Level | Low noise needs sleeve bearings16 | Household appliances |

| Precision | High precision needs jewel bearings17 | Clocks, measuring devices |

| Maintenance | Low maintenance needs magnetic bearings18 | High - speed turbines |

Making the Right Choice

- Assess operational demands.

- Match bearing type to application needs.

- Invest in quality bearings for longevity.

Conclusion

Understanding bearing types helps optimize motor performance. Choose the right one based on speed, load, and application.

-

Understand the various ways in which bearings impact the performance of DC motors. This includes aspects like reducing friction, enabling smooth rotational movement, and contributing to overall efficiency, which is crucial for optimizing the operation of your DC motor. ↩

-

Find out about different types of bearings used in DC motors. This knowledge will help you determine which type is most suitable for your specific needs, based on the performance requirements of your DC motor. ↩

-

Learn about ball bearings in DC motors: design, high - speed operation, pros & cons for high - speed setups. ↩ ↩

-

Discover sleeve bearings in DC motors: opération tranquille, durability under load, and HVAC/household fan applications. ↩ ↩

-

Understand roller bearings in DC motors: handling heavy loads, significance in industrial & conveyor applications. ↩

-

Find out about angular contact bearings in DC motors: supporting combined loads, role in high - speed applications. ↩

-

Explore thrust bearings in DC motors: handling axial loads, applications in vertical shafts & automotive systems. ↩

-

Learn about magnetic bearings in DC motors: contactless operation, no - lubrication need, high - speed/precision use. ↩

-

Discover jewel bearings in DC motors: low - friction operation, use in precision instruments like clocks. ↩

-

Understand fluid bearings in DC motors: load support with liquid/gas, applications in high - speed turbines. ↩

-

Learn the mechanisms of how bearings cut down friction in DC motors, which is key to understanding energy - waste minimization. ↩

-

Discover ways bearings control heat in DC motors, essential for maintaining motor performance. ↩

-

Find out how bearings boost the durability of DC motor components, beneficial for prolonging motor lifespan. ↩

-

Learn the reasons behind the suitability of ball or magnetic bearings for high - speed applications, which helps in making informed decisions when dealing with high - speed machinery. ↩

-

Understand why roller bearings are the ideal choice for heavy - load applications, useful for those working with equipment that bears heavy loads. ↩

-

Discover the reasons sleeve bearings are chosen for low - noise applications, beneficial for those designing or using products where quiet operation is crucial. ↩

-

Find out why jewel bearings are necessary for high - precision applications, valuable for those involved in the manufacturing or use of precision instruments. ↩

-

Explore why magnetic bearings are well - suited for low - maintenance applications, which is important for industries where minimal maintenance is a priority. ↩